Difference Between Squirrel Cage And Wound Rotor Induction Motor Pdf

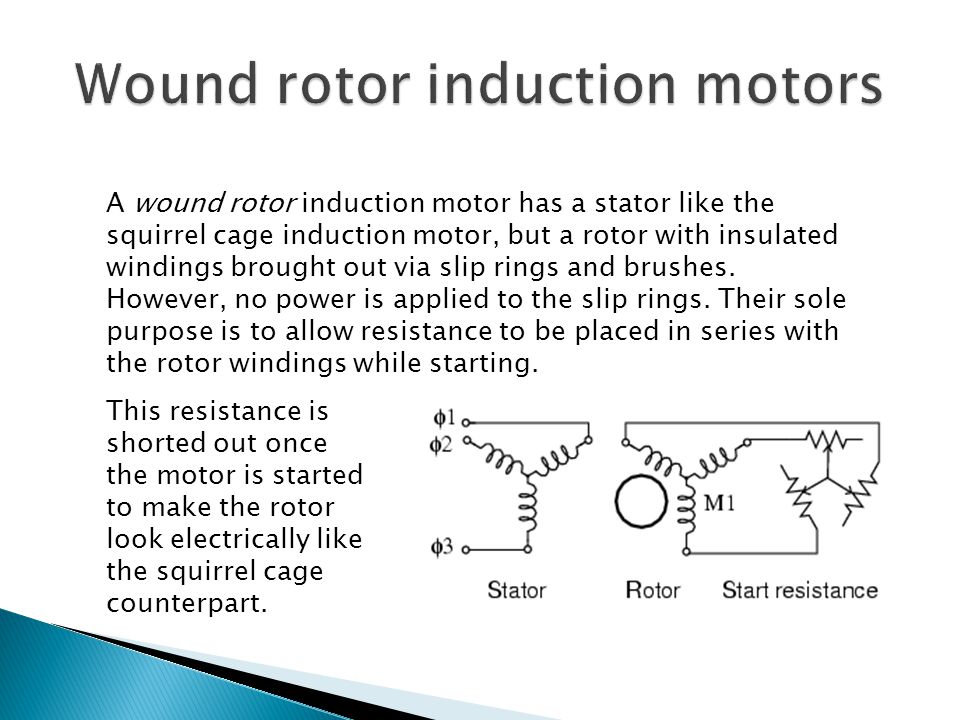

Know about the most popular and almost unbreakable construction of Squirrel Cage Induction Motor. Know about the different winding slots, lamination of the stator and its construction. Also appreciate the rugged construction of squirrel cage rotor and know the spectacular reasons for the skewed arrangements of the rotor conductors. Know how a rotating magnetic field is produced. Squirrel Cage Induction Motor: Slip ring (wound rotor) Induction Motor: In Squirrel cage induction motors the rotor is simplest and most rugged in construction: In slip ring induction motors the rotor is wound type. In the motor the slip rings, brushes are provided. Compared to squirrel cage rotor the rotor construction is not simple.

2014 For more information on: • 802.11 chipsets developed by Inprocomm before the acquisition, such as those having a chip name that starts with IPNxxxx, see. • 802.11 chipsets developed by Ralink before the acquisition, such as those having a chip name that starts with RTxxxx, see.

• Synchronous motor: Stator poles rotate at the synchronous speed (Ns) when fed with a three phase supply. The rotor is fed with a DC supply.

The rotor needs to be rotated at a speed near to the synchronous speed during starting. If done so, the rotor poles get magnetically coupled with the rotating stator poles, and thus the rotor starts rotating at the synchronous speed. • Synchronous motor always runs at a speed equal to its synchronous speed. Actual speed = Synchronous speed or N = Ns = 120f/P • Learn more about. • Induction motor: When the stator is fed with two or three phase AC supply, a is produced.

The relative speed between stator's rotating magnetic field and the rotor will cause an induced current in the rotor conductors. The rotor current gives rise to the rotor flux. According to, the direction of this induced current is such that it will tend to oppose the cause of its production, i.e. Relative speed between stator's RMF and the rotor. Thus, the rotor will try to catch up with the RMF and reduce the relative speed.

• Induction motor always runs at a speed which is less than the synchronous speed. • Synchronous motors require an additional DC power source for energizing rotor winding. Induction motors do not require any additional power source. • Slip rings and brushes are required in synchronous motors, but not in Induction motors (except wound type induction motor in which slip ring motors are used to add external resistance to the rotor winding). • Synchronous motors require additional starting mechanism to initially rotate the rotor near to the synchronous speed.

Third reich patch 138. No starting mechanism is required in induction motors. • The power factor of a synchronous motor can be adjusted to lagging, unity or leading by varying the excitation, whereas, an induction motor always runs at lagging power factor. • Synchronous motors are generally more efficient than induction motors. • Synchronous motors are costlier.